Attention to detail is a theme often highlighted by companies that focus on quality. But what does this mean concretely in large and small domestic appliances? We give voice to some brands in the sector to learn more about how attention to every detail is distinctive for a product

by Elena Corti

Under the expression “care of detail” a multiplicity of aspects gather together contributing to making a home appliance unique. Attention to the different elements that define a product in its entirety (even those that may seem more “trivial”) is a key factor to stand out.

«Details – says Paolo Mainardi, Brand Manager of Fulgor Milano – are an essential component of products, of which are an integral part increasing the quality perceived by the end user. Ergonomic knobs with an easy tactile contact, handles with a firm and easy grip, grids that slide in a fluid way inside the ovens, display with backlighting that simplifies reading, glass finished in the perimeters with soft solutions, oven doors that can be easily disassembled to simplify maintenance, more robust baskets of dishwashers and that are perfectly finished in the points exposed to contact, sheets with rounded edges to facilitate handling, handles on the sides of the ovens to simplify product assembly operations: these are all examples of the fact that details make the difference.»

The significant commitment by companies in finding design and construction solutions in the name of excellence rests on a way of conceiving the realization of products oriented to high quality standards and based on vast know-how that not all brands are able to offer.

«To make products paying great attention to details has always been part of our corporate culture – underlines Evelyn Passanante, Head of Retail Italy at Baraldi -. Not having visible screws, joining materials in an invisible way, having all the satin finish of the components in the same direction are small examples of the design and production efforts we continue to make to achieve the highest possible quality.»

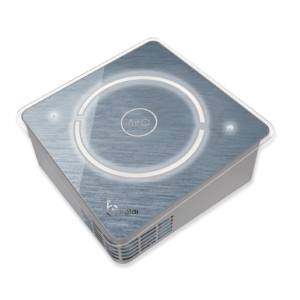

The Baraldi AirO’ range of air sanitizers includes the AirO’ desk model, available in black, white or gray and suitable for surfaces up to 20 m2. In addition to the cold plasma technology that eliminates pathogens, the product is studied in detail to be practical and easy to useIn turn, Lorenzo Poser, Falmec’s Marketing and Commercial Director, adds that «the quality of products is increasingly visible in the construction details. We take care of every single aspect, as well as every design detail, in a maniacal way. In the “constructive perfection” of our products we transfer the know-how and the Falmec philosophy: the expert eye recognizes them in the impeccable weldings, in the choice of the best materials and their combination. A significant example is the Lumina hood, in which a glossy glass front fits perfectly into a polished steel frame, an element that differentiates it from other simpler hoods on the market.»

Knowing how to manage all the steps of the production process, from start to finish, allows to keep every step and every small detail under control, as Zepa, which defines itself as a “one-stop-shop” company, is able to do. «Unlike others that carry out a simple product assembly process, Zepa has always taken care of every project starting from the design – explains Marco Zappulla, Sales Manager of Zepa-Teka Group -. In fact, thanks to one of the most qualified molding departments in the sector, we are able to create the project together with the customer, build the mold optimizing times and costs and take care of the molding phase thanks to very cutting-edge presses. Everything then culminates with in-line production, followed by a staff with thirty years of experience. We believe that being able to control the process from the design to the final product is strong evidence of the fact that in Zepa no detail is left to chance. The steel we choose is obviously the best on the market (AISI 304) and this also applies to products where price plays a very important role.

All the components purchased by us, as well as the steel itself, are internally subjected to continuous cycles of tests and “stress tests”, in order to guarantee quality over time to our customers. Another aspect that characterizes all our production of steel hobs is the silk-screen printing of the flames and symbols on our customers’ products: all this is achieved not through a simple “pad printing”, as is commonly the case, but thanks to our internal laser system; thanks to this, we guarantee the indelibility even after the heaviest use.»

A relevant factor in products with great care to details is the choice of materials. The most innovative companies carry out an important research activity to find advanced solutions both in terms of stylistic rendering and performance. «From an aesthetic point of view – explains Tiziana Prosperi, Technician Graphic & Design at Faber – the attention to detail is given by the study of the lines and shapes, but also by the choice of the type of material and the combinations. In Faber we have focused a lot on opaque finishes (Matt), used in contrast with glossy details and applied on metal, glass or innovative materials such as Fenix. The latter is not only beautiful, unique to the touch, but also functional because it is very resistant, waterproof, anti-scratch and easy to clean. It is a distinctive material, which allows a perfect integration of the hood in the many kitchens that use this type of surface, and which offers to the customer also advantages in terms of resistance and functionality. The new range of Soft Line hoods, made of Fenix, combines attention to detail with the philosophy of our company, for which design choices are never an end in themselves, but perfectly integrated into the performance of the appliance: hood must be beautiful but above all able to ensure the best suction performance. Another effective example is the new T-Shelf trellis hood, which is characterized by attention to detail, elegant and minimal design, as well as sturdiness: the mounting system has been designed to ensure maximum practicality and functionality, the aluminum profiles have pre-set holes and internal support for optimal coupling and no visible screws. The level of perceived quality is also made evident by the two finishes we have selected and by the smoked glass shelves, resting on a rubber housing integrated into the aluminum profile: a solution designed to prevent vibrations or accidental damage. The use of glass creates lightness and allows easier access to kitchen items. But that’s not all, the design of T-Shelf has been studied in order to enhance its linearity and create a unique game of volumes: the bars for hanging kitchen accessories perfectly symmetrical to each other and the centered lighting system as well as the rotary control allow to mount the hood body to the right or left by simply turning it in one of the two directions. These may seem like small details but they actually help to improve the structure of the product and its usability, and to protect it during the entire life cycle: in fact, details are those that characterize and personalize a project, on the one hand giving it personality, on the other contributing to increase the quality.»

«It is the attention to detail – adds Giorgio Grassi, Product Marketing Manager at Faber – that distinguishes a good project from a memorable one. It is an attention that concretizes in particular and exclusive materials, processes and finishes and in differentiating technological solutions. If, for example, we take into consideration the new Galileo hobs with integrated hood, we can observe that we have not limited ourselves to provide these products with maximum suction performance thanks to a suction power of 700 cubic meters per hour, but we have gone further by working on the capture power to maximize the effective speed with which a hood is able to capture the air, vapors or odors that come out from the pots, thanks to a fluid-dynamic system that allows to reach a capture speed of 6.6 meters per second. Another example of attention to functional details is the new Inside Up ceiling hood which offers a distinctive lighting component with a very sophisticated adjustment of the color temperature at five calibration levels – from a cold white light to a warmerr light – confirming how the attention to details is realized not only on an aesthetic level, but has the aim of improving and enriching the experience of using the product and forming a whole, perfectly integrated, between hood and home environment.»

Marco Guerzoni, Marketing Director of Glem Gas, also expresses a similar opinion, who highlights how attention to details also includes the functional aspects of the product, to offer appliances able to guarantee the best user experience. «Every single detail makes the difference – Guerzoni explains -, since it makes our product last over time and makes cooking (whether it is for necessity and/or for pleasure) be a simple, concrete and satisfying experience. The detail is designed and processed to be functional, to have a purpose, never for mere beauty, starting with the main elements such as the burner, the knob and the handle, ending with the brand badge, where a simple nameplate has the function of being an emblem and symbol of our identity, strengthening and consolidating it.»

If attention to detail is a distinctive factor in large household appliances, it is no less so in small domestic appliances (SDA), where just the total quality can allow to differentiate from competitors. Even in small appliances, the mix of high quality materials, innovative functional solutions and high performance is essential. Marco Di Leo, CEO of R.G.V., is convinced of this, explaining: « details that make the difference in our products are many, both technical and aesthetic ones. Among the technical ones I can mention the use of die-cast in lacquered aluminum with a double coat of paint for healthy contact of food with the parts of the slicers. Or the use of Tritan as a material for some components (for example the meat presser), which allows them to be easily disassembled and placed in the dishwasher for a more thorough cleaning. Another example of attention to detail is the Easy Clean system, recently patented by R.G.V., which allows to open the slicer plate and more easily clean the area below and behind the blade. As for the aesthetic details, I can mention the modern design and the ergonomic shape of our products, with the elimination of the corners in components and the rounding of the shape of the bases».

SDA companies that offer high quality products often transfer characteristics and solutions derived from the professional world to the domestic channel, where attention to the smallest details is fundamental. From the type of materials, to the sturdiness, up to the ergonomics and functionality, these products bring tools to homes that allow to obtain high performances in terms of reliability, precision, energy consumption, etc. «Reber has always been identified with reliable products with professional performance – Maurizio Re, Sales Manager of Reber, comments -. We offer solutions also for domestic use that derive from the professional world such as the possibility of continuous use without pauses to avoid overheating or, in recent times, the use of energy-saving solutions that favor the reduction of electricity consumption.»

Attention to detail is therefore a plurality of factors that together contribute to determine the perception that the user has of a product.

| «For us, paying attention to details means thinking about the product from an aesthetic and functional point of view in order to give it the best ergonomics, practicality and, at the same time, make the installation of the appliance as easy as possible.» (Falmec) |

A metter of quality

There is a close link between attention to details and perceived quality of the appliance, as end users are very careful in examining the products in every aspect. «Consumers – says Evelyn Passanante of Baraldi – are increasingly evolved and informed, therefore the overall quality perceived by the customer does not depend only on the high performance of the products but also on every detail, starting from the label on the packaging. From how the appliance is extracted from the box, from the ease of understanding its installation, from the intuitiveness of use to the maximum reduction in maintenance and required frequency of cleaning: all this is added up in the final quality rating attributed to the product.»

| «In the attention to detail, the aesthetic element is certainly a priority, but over the years the demand for products that are easy to use and install has required great attention to many details that before were hardly taken into consideration. The fact that about all our hoods can be installed by one person without assistance may seem trivial, but it took a great effort to make this possible by rethinking many details and with the study of the the easiest procedure. Filters, lights, motors and control are increasingly advanced elements, but that must make everything seemingly easy.» (Baraldi) |

And being able to make customers perceived the value of an appliance cared in any detail favors customer loyalty towards the brand.

«The quality of a product also depends on attention to details – Giorgio Grassi of Faber explains -. And this condition is expressed in particular in two moments: the first is that of the purchase, during which details help to convey the high value of the product. In short, when the customer makes his choice, the aesthetics but also other aspects (such as the robustness of the construction or the precision of the alignments of the components or the painting) transfer a high quality image of the product that adrresses the consumer’s decision. The second moment is that of the use, a phase in which the attention to details guarantees durability over time and maintenance of maximum performance.»

«It is precisely the attention to structural and aesthetic details that allows a positive product experience over time, up to the level of Faber’s brand reputation, and therefore to build customer loyalty by making him a promoter of the brand and its products – Tiziana Prosperi of Faber adds -. The more premium a product is, the stronger the link between perceived quality and attention to detail must be.»

| «Attention to detail must be expressed in all areas of the design of a hood, starting from the technical and engineering ones to optimize mass production; however, the utmost attention must also be guaranteed to other processes such as packaging and unpacking or proper maintenance by the end user. For example, Faber packaging can be different depending on the customer and the distribution channel: a cooker manufacturer who installs the hood directly has very different needs than the commercial partners who send the product to the final consumer.» (Faber) |

This attention to detail helps to fully meet the needs of consumers, strengthening the trust in a given brand that proves to be able to keep what it promises.

«Attention to details is on everything – Marco Guerzoni of Glem Gas says -. Our promise, which guides the development and creation of every single detail of our products, is that each model can offer the best user experience in our interpretation of Italian style, the Glem Gas style. So basically every single element, every single detail, must be designed and cared in order to be able to fulfill this promise. The main benefit we offer to our customers today is the creation of models with more attention to details and finishes, to make them safer and more excellent in cooking performance, essentially more and more of quality (and less expensive in price).»

In order to transform the attention to detail into quality appliances, it is important that the entire supply chain contributes to this goal, because the creation of a product conceived in its smallest detail is a teamwork.

| «Detailes are always those that make the difference. A motto that is valid in fashion, in the culinary art and in furnishing, and which is valid both from an aesthetic and functional point of view. Kitchen is the area of the house where functionality evolves faster than in other environments. In the kitchen we often choose practicality and comfort, but we also wish aesthetic elements in line with trends. In our Research and Development activities, also covering the role of Competence Center within our Group, we carefully study the best combination of these factors to always provide the best possible product» (Zepa-Teka Group ) |

«From raw materials, passing through single components to semi-finished products, the Zepa’s strict control begins already in the initial stages – Marco Zappulla of Zepa-Teka Group underlines -. The design of each product passes through a careful selection of the best is available today and at the best value for money. The quality of our finished products depends just on the attention to detail and the scrupulous choice of our suppliers, in some cases lasting for twenty years. A real teamwork. Each product line has its own quality certificate issued by our internal laboratory, IMQ certified, and supported by having reached the state of the art in all globally recognized quality standards.»

Attention to detail is therefore not a question of “meticulousness” but of contents (both formal and constructive) that denote the excellence of the product.

«Certainly the quality of an appliance also derives from the attention to detail – Marco Di Leo of R.G.V. affirms -, both technical details that lead to significant improvements, and aesthetic details that make the purchased product becoming the customer’s “own” one.»

On the subject, Paolo Mainardi of Fulgor Milano finds the comparison with fashion fitting: «a garment is pleasant if the fabric used, the seams and the overall shapes make it easy to wear and maintain – the Brand Manager explains -; the same is true for household appliances: an appealing design or an attractive price is not enough, content is needed so that the user can appreciate their intrinsic quality.»

The excellence deriving from the attention to detail is also what makes a product difficult to imitate, in a perspective that goes beyond the logic of a downward price.

«In a world in which we often see our products imitated and copied in design by our competitors – Lorenzo Poser of Falmec explains – it is important to recognize the difference in the constructive and functional detail, which is more difficult to imitate as part of the corporate heritage.»

«For Reber – Maurizio Re adds in turn – the quality of a product depends above all on the attention to detail in a market that often seeks only the lowest price. Not being able to compete with Chinese manufacturers on price, it is an obliged way to provide better products that take into account all the uses that customers could make of them. Our customers are passionate about cooking and “do it yourself” and often use our products much more intensively than even professionals.»

Attention to detail therefore becomes strategic for all those companies that make high quality the main strength with which to face the competition on the markets.

| «The attention to detail for us is mainly the use of quality materials, energy saving and high performance solutions. Particular care, in the design phase, is also dedicated to the simplicity of intervention for repairs or replacement of worn components: since our products are of the premium range, we also give the customer the possibility to have them repaired, or even to intervene directly, at low costs. The care we put into our products is demonstrated by the fact that we still receive requests for spare parts of appliances that are over 30 years old.» (Reber) |

The attention to details in Made in Italy

Historically, Made in Italy is associated with products that are not only beautiful to look at but also well built, in every detail. However, is this brand still synonymous with beautiful and well-made objects today? «Absolutely yes – Lorenzo Poser of Falmec says -. We think that Italy is still the country where “beauty” is born and develops, thanks to a cultural and manufacturing heritage unique in the world. For us, Made in Italy is not just a label, but a fundamental value and a competitive advantage. We produce everything at Vittorio Veneto, in the heart of the north-east of Italy: a unique territory where you can find equally unique skills and expertise, which we transfer to the quality and manufacturing excellence of our products.»

Similar opinion is also expressed by Marco Di Leo of R.G.V., who comments: «we strongly believe in Made in Italy that in R.G.V. is synonymous with craftsmanship in the realization of our slicers, assembled with special care, attention to detail and extensive know-how acquired in almost forty years of business.»

Made in Italy means in particular transposing into the product all those skills and values linked to the territory that make companies able to create appliances that have been studied in the smallest detail.

| «In our more than 60 years of history, we can say that the focus has always been to not neglecting any detail, be it an aesthetic detail of the product or a detail of the installation process. As “Specialisti in cottura” (cooking specialists) and manufacturers from Modena, Italians, we believe that attention to every single detail is the real added value we can offer to our users. Every detail was created and developed to be useful, functional, at the service of the user and not vice versa, therefore to contribute to the success of the product. The daily experience of the user is the driving element for us and the “beautiful but not functional” is not part of our corporate culture.» (Glem Gas) |

«We live in a land made of culture, passion for doing and desire to excel – Marco Guerzoni of Glem Gas explains – and we must not forget this first of all. This spirit and this historical heritage must be preserved and cultivated every day. How? Through the search of perfection, in doing the best by carrying out all our values, transposing them into design and construction of the product. Made in Italy does not merely mean building a beautiful and well-made product in Italy but inserting our land, our historical heritage, all our experience into the product itself. It means to go on evolving, carrying on and continuing to cultivate all this, our values recognized around the world, to ensure that “the next model is certainly the best ever”. This is the key element of Made in Italy, which will be able to defend and continue to promote our products. This is the strong interpretation that we carry out at Glem Gas.»

Even today, those looking for quality find in Made in Italy solutions that can satisfy even the most demanding requests.

«The value of Made in Italy – Tiziana Prosperi of Faber says – is recognized primarily on the high and medium /high end of the market, much less on the cheaper segments in which customers serch the lowest price, falling to inevitable compromise in terms of quality and performance. If, on the other hand, the user is interested in purchasing a quality hood, Made in Italy is still a guarantee of both design and reliability: I believe it is precisely this combination between the continuous development of aesthetically beautiful products, but also practical, useful. and lasting over time, the true differentiating content of the Italian production.»

| «Attention to detail must be expressed in all areas of the design of a hood, starting from the technical and engineering ones to optimize mass production; however, the utmost attention must also be guaranteed to other processes such as packaging and unpacking or proper maintenance by the end user. For example, Faber packaging can be different depending on the customer and the distribution channel: a cooker manufacturer who installs the hood directly has very different needs than the commercial partners who send the product to the final consumer.» (Faber) |

Furthermore, for many companies, keeping the quality of Made in Italy products high is strategic to differentiate themselves from increasingly fierce competitors.

«To compete against many imported products – Evelyn Passanante of Baraldi declares -, beauty and quality must remain absolute values for all Italian products. As for a fashion dress or a sports car, price cannot be the first lever, so for our 100% Made in Italy appliances, the elegance of design and the overall quality are the values we try to maintain at a high level. The Honorable Mention that our Diamond extractor hob received this year by Compasso d’Oro confirms that we are on the right path.»

| «R.G.V. mainly looks at functionality and ease of cleaning, which are the two musts that the end customer asks us with more insistently. But to fully satisfy the user, it is essential to carry out, upstream, a careful search for materials (increasingly ecological, removable and dishwasher safe) and, subsequently, an aesthetic customization with the introduction of the colored slicer base (not only gray) and silver colored knobs (not only black) and also in wood. These are purely aesthetic processes and finishes, which allow a product customization that harmonizes with the design of the home environment.» (R.G.V.) |

For small appliances producers too, the attention to detail that Made in Italy is able to express is essential to face competitors. «The “low cost “competition has significantly raised its aesthetic standards – Maurizio Re of Reber says -, so it becomes essential to enhance Made in Italy, to work precisely on details and performance, to provide added value that in terms of design only, in the SDA sector we are not always able to keep so high or so differentiated: only a few big brands are able to establish themselves in this way. But those who have not an “important” brand, need a combination of “beauty” and “quality”, besides a true Made in Italy not just an apparent one .» This last aspect is also highlighted by Paolo Mainardi of Fulgor Milano, who states: «if producers in general kept their promises, Made in Italy would actually still be a guarantee of beautiful and well-built products. Unfortunately, however, many products with an Italian brand are now manufactured in cheaper countries, making the affirmation of 100% made in Italy appliances more complex but at the same time satisfying and unmarking. Many markets perceive Made in Italy as synonymous with style, design and lifestyle: it is up to the manufacturers to strengthen these perceptions with the quality of the products and with the maintenance of the the promised contents.»

| «All parts that make up a product are subject to the care of details, because on the single ingredient usually depends the final result even in cooking recipes. There are processes such as the stain protection of steels which make their maintenance easier; enamelling and painting of the surfaces which, in addition to being aesthetically pleasing, are more durable over time; and anti-bacterial finishes in the interiors of refrigerators or cleaning functions of ovens with the pyrolysis system that reduce the effort and time taken by the user to perform the task.» (Fulgor Milano) |

Finally, Marco Zappulla of Zepa-Teka Group highlights how the concept of Made in Italy cannot be limited to the simple geographical provenance of the products and touches different areas that contribute to the creation of appliances with attention to every aspect.

«Considering Made in Italy only a reference of what is produced in Italy is reductive – Zappulla says -. Unlike other “production certifications”, which converge exclusively towards an idea of origin, Made in Italy must be interpreted as a signature or a brand and must convey the concept of special product for customers who want to differentiate themselves. For Zepa Made in Italy means “specialization” for which we are appreciated in the world. In a broader context, however, and including all our Group, this is also extended to innovation, design, after-sales assistance, prompt deliveries and value for money.»

| Kitchen: in every detail there is aesthetic beauty, but not only A fact that clearly emerges, when trying to define what “attention to detail” is in household appliances, is that it is too simplistic to limit considering exclusively the aesthetic aspects of the product. These are certainly very important (also because consumers themselves request appealing products and the manufacturing companies have been able to respond to this need with varied and refined proposals), but in appliances beauty can never be separated from functionality and every detail of the product must reflect this essential combination. This is particularly true for kitchen appliances, which require high performance but at the same time also aesthetic details, since they are exposed appliances. |